Learning to work on cars is challenging, fun and rewarding.

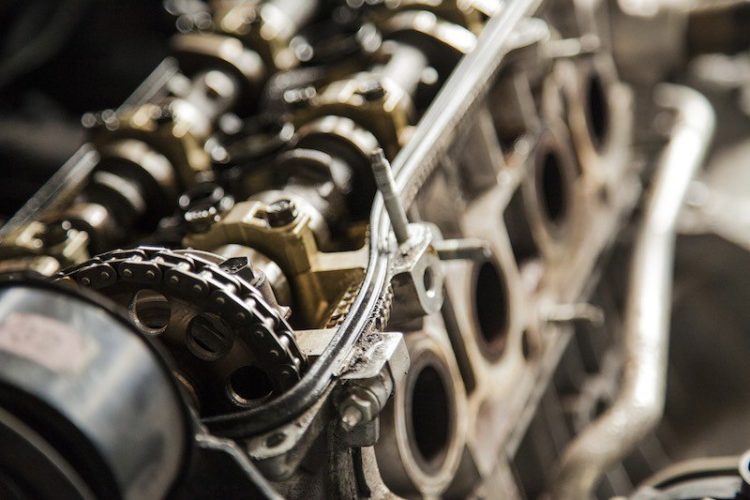

You’ll develop an understanding of how your car works. You will quickly start learning your way around your car and what all the different parts do.

Just as much as it is fun to work on your own car, you want to try to avoid making these five common beginner mistakes. I see it happen all the time with DIYer and YouTube mechanics, and I want to try to help you avoid making the same errors. Sometimes making mistakes is the best way to learn, however, I don’t believe that is true when you’re potentially putting other peoples lives at risk.

Table of Contents

5 Annoying Things Beginner Mechanics Do:

- Overtightening / Undertightening bolts

- Spilling oil everywhere

- Diagnosing other peoples cars with no real knowledge

- Rounding Bolts / Breaking Fasteners / Forgetting to put bolts back

- Using RTV / JB Weld / Duct Tape for all the wrong purposes.

#1: You Need a Torque Wrench:

This pet peeve of mechanics comes when they have to work on your car after you get done working on it. Most beginner mechanics and DIYers will often accidentally overtighten bolts.

It is probably better to just err on the side of being too tight, right?

Well, as a general rule of thumb, yes.

But, at the same time, a little bit overtight is okay, a lot bit overtight can cause the same problems as being too loose.

Also, you can overtighten lug nuts to the point where they break and it is now very unsafe to drive your car. I know from personal experience missing a couple of lug nuts can send your tire racing by you while you grind to a halt on three wheels. It is incredibly important to use a torque wrench, especially when starting out, for lug nuts, axle nuts, and brake/suspension related items.

When in doubt, err on the side of using the torque wrench. Or another guide for beginners is if there is a torque number in the service manual then use it. If you can’t find one, in the factory service manual from the dealership, then it probably isn’t a super important fastener and you just feel when it feels good and tight. I spent a couple of hundred hours developing a feel for torque, as any mechanic has, and the best way to do that is by following my guide here.

Snapping lug nut bolts, breaking valve cover bolts, and stripping Phillip head screws are some of the most common mistakes. They can make a repair that should have taken 30 minutes to take 3 hours. Usually,

Use a Torque Wrench, Then Develop Torque Calibrated Wrists:

Developing a feel for torque is something that takes mechanics years to develop. Also, a real high-quality mechanic will always use a torque wrench on lug nuts, engine components, timing pulleys, etc.

Part of being a good mechanic is grabbing a torque wrench, looking up the torque values, and torquing stuff down properly.

As a beginner or DIYer mechanic, you absolutely need to have a torque wrench. You need to be using it on basically everything when you start, so you can develop a feeling for torque. I wrote an article where I talk all about some awesome ways you can learn to torque things properly fast here.

I also spent a week researching torque wrench myths so you can be a pro the first time you pick one up, read that article here.

If you’re looking for an awesome middle-of-the-line torque wrench I searched Amazon for the best value and found this awesome 1/2″ drive torque wrench for the DIYer. I am kind of amazed it is so affordable on Amazon, and expect the price will probably increase soon. A 1/2″ torque wrench is the best size for tightening lug nuts, brake caliper hanging bolts, and most everything you will be doing on your car as a beginner.

If you’re working more on smaller engines and motorcycles I found this awesome 3/8″ drive torque wrench on Amazon, it is perfect for the smaller torque values found on motorcycles. Plus, you really can’t beat that price.

#2: Spilling Oil Everywhere

Changing oil sucks. Especially if you are working on the ground and don’t have access to an automotive lift. I have spilled so much oil everywhere. I apologize profusely to the environment for this. It seems somehow that every new DIYer mechanic must make some kind of ceremonial spillage to the mechanic gods when they first start.

I looked down in horror to find the puddle of fresh oil, 4.5 quarts to be exact. The look on her face was pure disgust and she immediately went from being nice to being very short and rude. I apologized profusely and drove immediately to the auto parts store, bought new oil, and didn’t charge her for the oil change.

I have also have forgotten to take the plug out of the plastic oil drain pan I was using. I pulled the engine drain plug and expected the oil to start filtering into the plastic tub I had positioned below. I gasped in horror as the oil quickly overfilled the top reservoir and started pouring out onto the ground. I spilled around a quart of oil before realizing I had forgotten to pull the plug in the top of the drain pan. Oops! That didn’t make the neighbors happy.

I really don’t enjoy changing the oil on any vehicle anymore. Oil changes are usually messy, hot, and ruin your clothes fast. I find now, that it is one of my least favorite maintenance items on a car to do.

That being said, I have gotten 100 times better at not spilling oil everywhere anymore. I also have figured out how to make oil changes as easy as possible. A lot of these tips aren’t the ones you will find on YouTube, or if you do, they are buried at the bottom.

For a tip on how to remove the oil filter without it dripping all over you click here.

To read about how you can change the oil on your engine like an airplane mechanic would click here.

The main things I have found that will make your oil changes much easier is using a pair of high-quality automotive ramps, like this sweet deal on Amazon.

Those will help you get the car high enough that you can get under it with a creeper fast and start the oil change. Using a creeper really helps to keep you from straining your neck or back, and is an absolute essential professional tip. If you’re going to be working on the ground you need to have a creeper. There are a ton of super cheap junky creeper out there, but I asked some of my professional mechanic friends and they said this creeper is the one to have hands down. Luckily, it is on Amazon for an awesome deal.

#3: Stop Diagnosing Friend’s Cars With No Real Data:

This is a huge pet peeve for any mechanic and it will be sure to cause you grief if you act like this in front of a mechanic. They may not say anything to your face, but they will make fun of you behind your back. I know personally I immediately stop caring about helping someone who is intent on telling me what is wrong with their car.

If you know what is wrong, then fix it! Stop telling me about it. Anyone else ever felt that way?

It is okay to admit when you do not understand what is happening with your car. In fact, many mechanics will respect you much more if you tell them you tried figuring it out but failed. They will likely take the time to explain it to you, versus if you try to act like you know what they’re talking about.

The flip-side of this coin is that if you actually do your homework and know about your car and the problem then you can be a great help to a mechanic.

For example, your car is making a noise that you want the mechanic to check it out.

You can either go to the mechanic and say your car is making a noise.

Or…

You can say your car is making noise, if they want to get the noise to happen they need to be in drive going 5-10mph and make a sharp right-hand turn. It does not make the noise turning left, and the noise can not be heard at any other driving speed or in reverse.

Provide Direct and Honest Information About Your Car’s Problem:

By giving the mechanic direct and specific information about when the problem happens you make their life 10x times easier. Your car problem will be faster to diagnose and will save you money.

Therefore, just because you’re learning how to work on your own car does not make you a professional level mechanic. You should not be diagnosing other peoples cars just like professional mechanics do not diagnose peoples cars over the phone or without any real information.

You just don’t know enough to ever draw a conclusion unless you have a ton of information and trust the source. Therefore, you recommending your friend change their spark plugs because their car has a check engine light– is not useful! You just don’t know!

#4: Rounding Bolts and Using Wrong Tools

I basically already covered this in my previous post about over-tightening and under-tightening bolts. But this is a different animal.

Beginner mechanics or DIYers will often buy pretty cheap “mechanic toolsets.” These tools, more often than not, aren’t very high-quality and can actually lead to rounding off or breaking bolts at a much higher rate. That is because they don’t grip the fastener well. You will end up rounding more bolts using cheap tools.

Another huge problem, and one that will cost you a lot of time and money is using the wrong tools for the job. Beginner mechanics want to save money buying tools so they often buy gimmicky tools that don’t work well. If the tool says it does everything you could ever ask for, then it likely does nothing well.

Trust me, I have been there and done that.

Avoid Gimmicky Tools That Don’t Work:

Read here for my post on gimmicky tools and see if you own any of these.

If you’re going to do oil changes or any work on your car, please put down the adjustable crescent wrench. They have some uses, but I assure you they will do more damage than good at first.

You really need a high-quality ratchet set and sockets to start. Both of those links go to my favorites on Amazon in 2019, and both are at a great price. Those will treat you much better than any cheap mechanic toolset and are a great start to building your toolbox.

#5: There Isn’t Always An RTV or Epoxy To Fix Everything:

The truth is RTV, epoxies, and duct tape all are very important, but only in certain circumstances. Duct tape will not fix your ripped CV axle boot. RTV will not fix your busted engine mount. And JB Weld isn’t meant for welding shut your cast iron header’s exhaust leak.

Unfortunately, many of the people working in these chain automotive parts stores don’t know anything about cars.

They are some of the worst people I have found for asking for advice with car repair. You are better off banging your head against the wall and seeing if anything comes to you. They need all the help they can get just to make sure you get the right part.

You may have a problem with snake oil products if:

You respond to these word associations with the following answers.

- Exhaust leak? Do you say? JB Weld.

- Window won’t stay up? Duct tape.

- Leaking oil pan gasket? Needs more RTV.

- Ripped CV axle? A plastic bag and some zip ties?

Look, you will see these kinds of “hack” fixes day-in-and-day-out if you work on many cars at all.

People put way too much faith in certain products because they want them to work. If an exhaust leak was always just as easy as squirting JB Weld in it that would be great! The problem becomes when these fixes put real people’s lives at risk. Messing with the brakes, or the driving or the tires on a car can have real-life consequences. Please don’t take these things lightly.

The reality is a lot of these fixes don’t even temporarily work and end up making the next person to work on the cars life harder. Ever tried removing duct tape glue from a window? It sucks.

Or scraping off endless RTV from an oil pan? It takes forever!

Don’t get me wrong you should definitely use RTV when it is called for. Duct-tape also serves its purpose, as does JB Weld, but I assure you-you’re probably using it way too much if you reach for it more than once a week at most.

I spent a ton of time writing an article on how using RTV correctly is dead. You should read it here and it includes a ton of tips for choosing the right RTV and using it correctly.

The Verdict:

People make mistakes. I have made tons working on cars. The real mistakes are the ones that involve actual safety issues. Don’t put your life at risk or others around you by trying to save money buying cheap jack stands.

I didn’t even mention that one of the more common things beginners do is not protect themselves correctly. You need to be using jack-stands at all times! Even if you’re just changing a tire, please get in the habit of busting out the jack stands.

Also, another warning is that buying cheap tools can come back to bite you in the butt. You don’t need to be buying Snap-On tools, just please make sure you get better than the absolute cheapest junk. That is the point of this site, to help you find the best tools that offer the highest value.

Don’t skimp on the items that really matter for your safety. Jack-stands, jacks, and personal protective equipment can all save you from bad injury or death.

If you want to brush up on some old school mechanic tricks click here to read my article where I go through 10 of my favorite tricks.

Fess Up When You Screw Up:

Always fess up to your mistakes! Do not try to hide the reason why you came in for a repair. For example, the number of mechanics that have had a customer claim their “…car just died while I was driving.” They then spend an hour trying to diagnose what is wrong. They then find you had clearly money-shifted and were too embarrassed to admit it.

Well, you would have saved yourself about $120 for an hour of labor. And the respect of all the mechanics had you just fessed up to it. Some of them would’ve probably said they had done the same thing.

They’d make sure you got the best deal on a used engine. Instead, they are going to charge you $120 for a diagnosis they didn’t need to do. I guarantee they won’t feel inspired to help you look for a great engine either.

They are also going to talk about you behind your back when you leave. I don’t like being made fun of.

Just don’t be a chump. Mechanics will respect you a ton more if you come clean about your mistakes. I am sure they have done much worse than you can ever imagine.

Pingback: Best Starter Mechanic Tool Set Under $100 - AGradeTools.com