Table of Contents

Beginners Guide to When You Must Use a Torque Wrench:

If you don’t know what a torque wrench is, simply put, it is a ratchet that you set to a specific torque value. When it hits that torque value, as you initially set (say 85 ft-lbs), it will alert you in some way. Usually, torque wrenches for mechanics are the click-type where you will hear and feel a click as it reaches the set torque value.

It is so you can make sure you are installing parts to the correct torque specifications.

This is the only safe way to tighten fasteners on a car or truck. Especially when working on brakes, rebuilding engines, and changing tires. As you work on cars you will develop a feel for the correct torque for certain applications and different sized bolts. Before you have developed that feel, please use a torque wrench on anything you are unsure of.

You should always use a calibrated Torque Wrench whenever you are:

- Changing tires especially lug nuts

- For any specific bearing application, idler pulleys, water pump bolts (anything very important)

- Any internal engine components: bearings, camshafts, head bolts, drive axle nuts, brake work, etc.

- If you are a beginner make sure to use a torque value on any fastener that the Factory Service Manual lists a torque value.

With some of these torque values, you will develop a feel for proper torque over time. However, for lug nuts, engine components, and other more serious important bolts you should always use the proper torque specifications directly from the Factory Service Manual for your car.

I have personally lost a wheel on the freeway due to not torquing my lug nuts properly.

Please don’t learn the hard way like me!

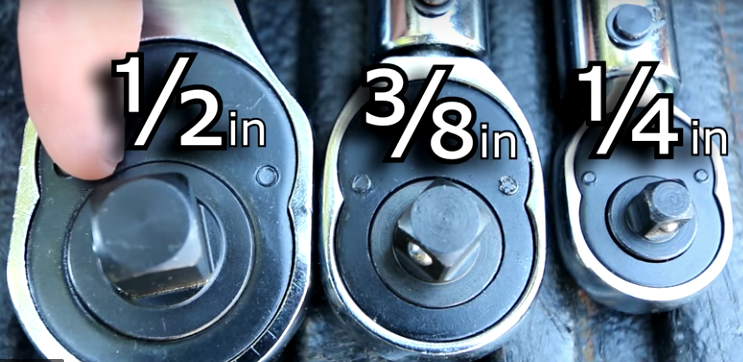

My three favorite torque wrenches are as follows (links to Amazon) 1/2″ Favorite in 2018, 3/8″ Favorite, and my 1/4″ favorite.

You Can Learn To Know When A Bolt Is Tight Enough:

Here is the SHOCKER!

Technicians are not looking at torque specs for every bolt on your car. Even if they know it is in the Factory Service Manual, they are not always going to look and torque every bolt to spec.

But but… You pay them 120 an hour and they aren’t torquing to spec every bolt?!

If they’re a high-quality tire shop then they will start the bolts with the impact gun, then go back and do the final tightening with a torque wrench. That’s if they’re a high-quality tire shop (or just have good practices).

Do all tire shops even use torque wrenches?

Heck no!

Why would they do that, when they can just turn the gun up and hit him on full blast?

I always ask a tire shop before they start working, can you please torque the wheels with a Torque Wrench to (insert the torque spec you want here).

Do they look up your exact factory lug nut torque spec on your 2016 Mazda 3? 95 percent of the time they aren’t!

Some good general guidelines for torque values on lug nuts:

Most smaller sized cars with a normal amount of lugs nuts are usually around 80-90 ft-lbs. I typically use 85 ft-lbs on all smaller sized cars and look up the values if it is at all a heavy duty truck or van. Those torque values are usually around 120-150 for lug nuts. So, if you can’t get access to a computer to google the exact number on your car you can use these general guidelines. The one thing to keep in mind is if they’re aluminum rims on either a truck or car, you should recheck the torque after 1,000 miles. They have a tendency to loosen up over time.

For these items, is a high-quality torque wrench absolutely necessary? YES! Really? I can’t just use my $10 Harbor Freight Special for the head bolts in my VW GTI? Sure, you can. Should you? Probably not.

Should every home mechanic or DIYer have a 1/2″ drive torque wrench for lug nuts? Yes.

Do they also need to be torqued to spec their timing belt cover bolts down to the inch-pound? No.

Are You An Absolute Car Repair Beginner?

If you’re an absolute beginner with no hand feel developed then you should be using a torque wrench on EVERYTHING. You need to also understand that installing bolts “dry” is different than “wet” torque values. When a bolt is lubricated, anti-seize or grease for example on the threads, you need to decrease your “dry” torque values by around 20%. Most torque values are given “dry” unless specified as “wet” torque values.

To get a feel for what is a good torque relative to the bolt size.

You should be torquing your timing belt cover bolts to the torque spec in the factory manual.

You will start to develop a feel fast for different torque specs “feel like.”

Expert technicians, shade tree mechanics, and the grease monkey down the street all have developed over time a feeling for torque. It is a feeling you just get used to with time, time spent wrenching on everything with different sized wrenches, ratchets, breaker bars, etc.,

How do you gain a feeling for the correct torque for different bolts?

You break bolts, you snap things, you curse and swear and learn.

Just watch the first 30 seconds of this video by Eric The Car Guy. He explains how breaking bolts is just part of the process.

How To Not Overtighten Lug Nuts:

I had a good friend who must’ve weighed 200-250 pounds who called me after snapping two of his lug nuts on his Toyota Camry. He was calling to ask me if there was a problem with the bolts, or was he tightening them too much?

I laughed and said yes, you’re definitely tightening them too much.

“How’re you tightening them?” I asked.

“Oh, I put the tire wrench thing that came with the car on them, then I jumped on it till it stopped tightening.”

Laughing. “Yeah, Andy you’re a big guy. You do not need to jump on the wrench!!! Dude, just put them on pretty tight using the wrench and just using your body weight to push down. Drive it over here ASAP and we will fix the two studs.”

“Well, I already tightened all of them by jumping on them. Only two broke through. Can I please bring it over so you can fix it?”

“Sure,” I sighed laughing.

I hang up and go make sure my Milwaukee 700 ft-lb impact gun has two full batteries. Jeez, I hope this thing can take them off.

Wow! He had exclaimed after I gave him a lesson in torque. That isn’t nearly as tight as I thought man! You’re right Andy. You’re right.

My friend Andy made a newbie mistake, luckily it wasn’t a big deal.

I have broken my fair share of nuts, lug nuts, and other fasteners. If you are a good technician that works often, you will break your fair share of bolts as well. Might as well be as prepared as possible to avoid those situations. If they do happen, you need to be sure you have a game plan in place to remove the broken fastener.

Breaking Bolts as a Beginner is Okay:

Breaking Bolts as a Beginner is Okay:

Like losing a 10mm socket. You will do it, it is just a matter of time.

Best do it in a safe place (no risk) as much as possible to develop your feel.

Had my friend ever used a torque wrench before and felt what 85 ft-lbs felt like, he would’ve never sheared two lug nuts.

Want to know a shortcut to gain a feel for what torque breaks bolts/lug nuts?

Find the closest Pick-N-Pull or other similar junkyards where you can walk around and pull your own parts.

You will need:

Bring a 1/2″ breaker bar.

3/8″ drive long handled driver.

Sockets that can take a beating. Impact sockets for the impact gun.

Ear Protection / Eye Protection / A Camera for Fun.

And whatever portable impact gun you’ll be using when you work on cars. Don’t worry about it if you don’t have one.

Learning Torque Values By Breaking Bolts:

People aren’t going to like me for encouraging this. In fact, I am sure I will get blowback. But there is a simple truth, the more you break bolts the more you develop a feeling of when a bolt is right about to break. Therefore, you can practice breaking bolts on cars that you don’t care about. The best place to find tons of cars that no one cares about and plenty of bolts to break is your nearest pick-n-pull. My only advice is to pick a car that is the least wanted car on the lot.

1. Find the most mangled car. That isn’t a car many people will want parts from (to be nice). Usually like a Mercury Villager van in the far back will work great.

2. Start breaking stuff. Try some small bolts first (10mm, 12mm, 14mm) get a feel for when they feel tight then go past that. Break them. Snap, shear, rip out, bust every bolt you can find.

3. Work your way larger, put a cheater bar on the breaker bar and go after some 17mm or 19mm bolts and try to snap them.

4. Feel how tight they get. Feel that feeling a bolt makes right before it shears or snaps. Remember in your mind’s eye what that feeling felt like, and how big or small the bolt was.

Watch this guy break bolts on his YouTube Channel. I suggest you do the same.

5. Hook up your impact gun and do the same.

How close can you get before snapping a bolt?

Can you start to feel when it is about to break?

Can you even break a lug nut with your impact gun on full blast?

Check how tight it is after with your breaker bar and see how tight your impact will actually get certain bolts.

6. Do this with Spark Plugs. Find a car no one will care about, and has easy to access spark plugs. Over tighten the crap out of a spark plug or two. Go beyond that. Strip out the head. Feel it. Enjoy the destruction. Explore the damage you just caused.

If this was a customers car, how do you proceed?

Why breaking stuff that isn’t important is good:

If you can prevent breaking bolts on customers cars you will save yourself countless hours and headaches.

Removing broken bolts isn’t easy, and is a science in itself. The best technicians in the world try to avoid breaking any bolt as hard as they can, but if it happens they’re fully prepared to remove them.

If you really want to be a boss. Go to pick-n-pull and break off a couple fasteners in a intake manifold or valve cover gasket. Now, think about how you would remove those / give it a try. Bring your removal tools. After, find rusty bolts that look like they’ll be trouble and think about how you would address those first before trying to remove them.

Would you hit them with a torch first?

Soak them in penetrating oil?

Use an impact driver or just a breaker bar?

Stuck bolt lifehack trick:

These are all questions that you need to explore and find what works for you. Quite often a mix of all three is what works best. Spray penetrating oil, let it sit, hit it with a torch, work it back and forth slowly, rinse and repeat.

If you rush it, the chance you break the bolt goes up dramatically.

I use a mixture of all three of those things depending on how bad the bolt is, and how much I want to be sure I mitigate the risk of snapping the bolt.

Watch countless YouTube videos, read the forums, and then figure out what works best for you.

This looks like a pretty awesome trick. Get yourself a torch and a bar of wax and try this.

I have yet to try this, but I sure will next time I see a rusty bolt.

Do you have a game plan when you encounter a bolt/nut that looks like this?

OR that?! Just gross rust.

These are some products I use daily while working on cars.

Use anti-sieze on any bolt reinstall you are suspicious might get rusty in the future. Excep for some obvious exceptions (engine components etc).

If you break a fastener do you have a game plan?:

Have you practiced with your removal tools?

Click here for a great article about all your options for removing broken studs / fasteners. It all depends on how far down it is broken / your access. I suggest practicing all of these on non vital bolts. Do this in a vice, and get good at it. Watch YouTube Videos and find out what the professionals use.

When is it good practice to use a Torque Wrench?

In a perfect world, every technician would be using new bolts for everything, and torquing everything to spec. With a torque wrench that just came back from the laboratory in a weather sealed box after receiving a complete calibration down to 1 ft-lb.

In the real world? Every technician has different torque wrenches, calibrated well or poorly. Most technicians use their torque wrench with different frequency. Some technicians may feel more or less comfortable doing certain bolts by feel, and others using only the torque wrench.

To reiterate if you’re a beginner or DIYer:

In the beginning, you should use a torque wrench for everything. Develop a feel, then slowly phase using less and less for non vital bolts and nuts (like timing belt covers / oil pan drain bolts / alternator mount bolts etc etc.,)

Once you have developed a great hand feel, when is it good practice to use a torque wrench?

1. All Lug Nuts. This video will walk you through why it is important, and how to do it safely. Can you still safely put a spare tire on if you’re on the side of the road without your torque wrench? Yes! Just get that good hand feel developed, and if you have the torque wrench in your toolbox you should definitely bust it out for all lug nuts. For peace of mind knowing you tightened everything correctly. It is a great habit to have.

2. Any Internal Engine Bolts / Fasteners.

Are you replacing a head gasket? You better be looking up the torque specs for the head bolts. Watch this video to see what that sequence is like on a specific Honda. Hint: It is different for every car / engine.

Changing camshafts? Yes, you need to be using a torque wrench.

You need to be following the EXACT specified sequence in the Factory Service Manual in many cases when rebuilding engines or doing any internal engine replacements.

You need to be using a reliable torque wrench. This means spending a little bit more on it than the special at Harbor Freight. Especially if you’re going to work on anyone else car. You’re putting their safety and the longevity of their engine on the line. A torque wrench is not a tool to skimp on.

Why so many other online review sites get it wrong:

Today, in August 2018, I searched google for “best torque wrench 2018.” One of the top websites to come up, had poorly written articles. Here is what I found when I clicked on one of their recommended torque wrenches in 2018.

Looks pretty promising and like a legit review website right?

I decide to click on the Neiko 00206A 1/2″ they have at number 4 on their recommended torque wrenches of 2018 list.

Here is what I was linked to:

Hmm. The link to Top 2018 Torque Wrenches takes me to a link on Amazon of a Breaker Bar?!

Needless to say this top ranking site, isn’t actually giving legit reviews of anything.

They aren’t even linking to products that are the correct type of product.

A breaker bar is not a torque wrench, and they’re completely different tools. With two completely different purposes.

I didn’t want to make this article a tool review or tool buying guide for torque wrenches. But I think it would be irresponsible to leave you here, without recommending to you the right tools.

When there are plenty of others out there with no idea what they’re writing, posting tool reviews with no experience at all.

Here we go then.

My 2018 Recommendations For Torque Wrenches:

If you’re just getting started in car repair stick with a 1/2″ Torque Wrench first.

If you find you need it then buy a 1/4″ Torque Wrench.

And lastly, if you find a need for it buy a 3/8″ drive torque wrench.

I find 90 percent of the time for beginners a 1/2″ torque wrench will suit your needs.

Unless you’re jumping right in to rebuilding engines. Then get the right torque wrench for the torque range you will be working in.

1/4″ is best for tight spaces on scooters, motorcycles, and small engines where the torque values are small (in inch pounds or low ft-lbs).

1/2″ Torque Wrench W/ Adapter Set Or Same Set W/ A Breaker Bar

The beauty of this is that it also comes with an adapter set (for an extra like $10 or less).

You can use this as a torque wrench with different sized drive sockets (1/4, 3/8, and 1/2″). The only problem is that its minimum torque capacity is 10 ft-lbs which is 120 in lbs roughly. That is too much for many 1/4″ fasteners, meaning the torque wrench won’t be able to be used for all 1/4″ torque specifications. You would need a smaller torque wrench 1/4″ or 3/8″ that can handle the specifications for your torque values.

MYTH: Putting Adapters On Torque Wrenches Changes Their Torque Values:

You can use as many extensions as you want, and as many adapters as you want. These do not change the torque values. Read more about that myth here and here.

They also make this same torque wrench that also includes a 1/2″ breaker bar.

It is essential that you have a breaker bar as a partner to your torque wrench. Why?

You should never use your torque wrench to break lose tight fasteners or as a regular ratchet. It is a special tool that should only come out to torque down fasteners.

If you don’t already have a breaker bar, I recommend buying them together in the package (check price on Amazon here)

For Professional Use / Semi Professional I Recommend This 1/2″ Torque Wrench:

It won’t break the bank like a Snap On breaker bar or other big dollar brands. But it will last a dang long time. And usually sits at less than $200, with amazing reviews. It also will go from 30ft-lbs to 250. Check price on Amazon here.

3/8″ Torque Wrench Favorite in 2018:

I don’t think the 3/8″ version you should be buying cheap. You will usually be using it for more precise measurements than the 1/2″ Torque Wrench.

This is a good mix of high quality, and value for your money.

It will serve you well for many years if taken care of, and not bust the bank.

However, since 3/8″ drive torque wrenches are usually used for more exact torque specifications, I recommend not just buying the cheapest one on Amazon.

It is much more important if your torque wrench is accurate when doing head bolts, versus lug nuts. That is why I recommend this one also by Capri Tools (click here to check price on Amazon.)

So please don’t skimp on your torque wrenches, especially the 3/8″ and 1/4″ ones.

1/4″ Torque Wrench Favorite in 2018:

If you aren’t going to buy a high quality 1/4″ torque wrench, just save your money.

A lot of the specifications you will be using with a 1/4″ Torque Wrench, are really really exact. You want to get them right.

You want to trust your torque wrench.

Believe me don’t skimp on a torque wrench. From my research I really like the price and how accurate this 1/4 Torque Wrench from Capri Tools is. Click link to check the price on Amazon.

It is highly reviewed and a 2018 favorite.

Now that you know my favorite Torque Wrenches in 2018.

You need to know how to use them / store torque wrenches:

ChrisFix does a great job in this video explaining everything you need to know about how to properly use a torque wrench. Don’t look like a jerk if you borrow one from a mechanic.

Thanks for reading if you decide you want to try out some of these tools before you buy them, try finding a local DIY Automotive Repair Shop near you. You may be able to rent a lift, that comes with a toolbox full of professional tools. That way you can get a feel for using torque wrenches, and decide which one you want to buy.

Click here to read my article about these DIY Rent-A-Lift type shops.

Breaking Bolts as a Beginner is Okay:

Breaking Bolts as a Beginner is Okay:

Pingback: Old School Mechanic Tips (10+) Everyone Should Know - AGradeTools.com

Pingback: 5 Annoying Things Beginner Mechanics Do - AGradeTools.com